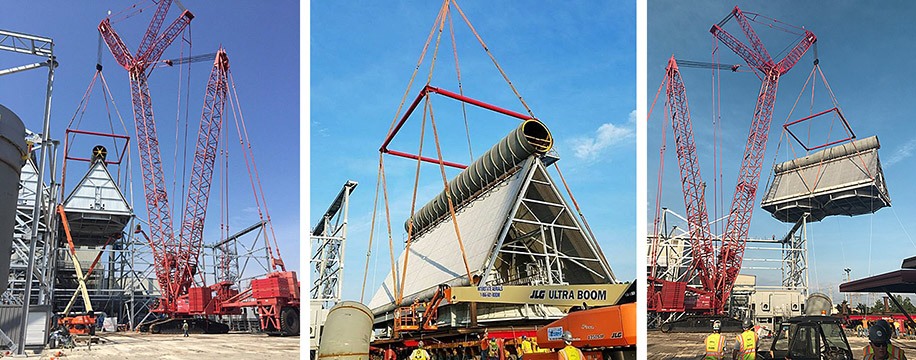

Maxim Crane Works L.P. was contracted to provide lifting services for a mechanical contractor at a New Jersey power plant. Maxim’s scope was to lift air-cooled condenser (ACC) units from a heavy-haul unit and set them on top of a 75-foot-tall structure. On the project, Maxim was to make 12 lifts: eight double ACC module lifts weighing 260 tons each and four single ACC module lifts weighing 130 tons each.

Pre-planning started early in 2017, and a Manitowoc 18000 with MAX-ER was selected to make the lifts. In mid-April, Maxim’s engineering group was consulted and tasked with developing a wood mat support system, lift plans, and rigging designs. Several key factors were evaluated early on, including hook height, capacity, rigging arrangement, and rigging weight. The group determined traditional spreader bar systems were too heavy and consumed excessive vertical space for the crane to make the lifts, given the crane configuration and ACC module lift weights. Additionally, as the project progressed, the weight of the double ACC module was increased to 295.2 tons – a 14% increase over the pre-planning lift weight. The increase in weight required a careful review of each piece of rigging.

For the Manitowoc 18000 to complete this project effectively, the engineering group needed to come up with an alternative approach to the rigging. A lift frame concept was conceived and adopted. A major driver of the design was the requirement to use off-the-shelf materials, due to the extremely compressed schedule. Because the crane was approaching capacity limitations, it was essential that the lift frame be structurally efficient. From designing to load testing, lift frame development took only 19 working days.

The load test was successfully completed on July 5, with the 300-ton rated lift frame lifting a weight of 377.8 tons. Immediately following the load test, the lifting frame was disassembled and shipped to the project site for the first lift on July 7.